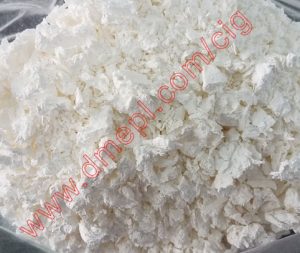

Cellulose acetate (CA) is a chemically modified form of cellulose as an acetate ester, which is a biopolymer obtained from cotton or tree wood pulp of managed forests. Cellulose acetate flake is a bio-based product with many applications.

Technology

Cellulose acetate is the solid product obtained from the acetylation of cellulose. It is manufactured by reacting wood pulp or cotton linters with acetic acid or acetic anhydride in the presence of sulphuric acid. When the cellulose is fully acetylated and the sulphuric acid has caused appreciable degradation of the cellulose polymer, the cellulose acetate is partially hydrolysed by the addition of water to give a thermoplastic product which is soluble in acetate. It need can be in flake form, powder, granules or fibre.

Uses

Cellulose acetate flake is mostly consumed as raw material in one major application—the production of cellulose acetate fibers for conversion into cigarette filter tow and textile fibers. CA Flake and the mixed esters are also used to produce transparent thermopolymers.

These thermopolymers have exceptional clarity, good mechanical properties and are easily coloured.

The Cellulose Acetate flake is compounded and used in injection moulding, extrusion compunds, film, sheet casting (from solution), photographic film, coatings / inks and cellulose triacetate for polarizer protection films used in liquid crystal displays (LCDs).

The ageing properties (non-yellowing and resistance to embitterment) and other physical properties of CA films are far superior to those of regenerated cellulose film (cellophane).

cellulose triacetate for polarizer protection films used in liquid crystal displays (LCDs) account for the remainder.

CA plastic applications are niche markets, which demand its clarity, high impact strength and chemical and solvent resistance.

Supply Ability

As per the industrial requirement, we can provide different grades of Celullose Acetate flakes (including diacetate and triacetate) to match your needs for applications such as:

- Cellulose Acetate Tow

- Textiles – Fibers (mono and multi filament), yarns, apparels, home furnishing, etc

- Paper Sheets and Films (with good barrier properties)

- Replacement plastic applications for automobile industry

- Coating and injection molding applications in Electronics, Toys and other industrial applications.

- Screwdriver handle and other handtool grips

- Writing pens

- Eye glass frames

- Pharmaceuticals (as filler and stabilizers)

- Touch Screens and protective covers for Mobile Phones

- LCD / LED layering sheets

- 3D printing material

Characteristics

The best part which makes the use of cellulose acetate flake more attractive is the characteristics:

- Compostable and easily incinerated

- Easily bonded

- Wide variety of plasticizers for cost effective production

- Soluble

- Selectively absorbs

- Hypoallergenic properties

- Versatile

Health and safety

There are no hazardous problems associated with the produced polymers. However, during manufacture there may be exposure to solvent and organic compounds which can result in skin reactions.

Solvents which are evaporated during the spinning or other processes must be exhausted to avoid risk of fire and explosion and possible health hazards.